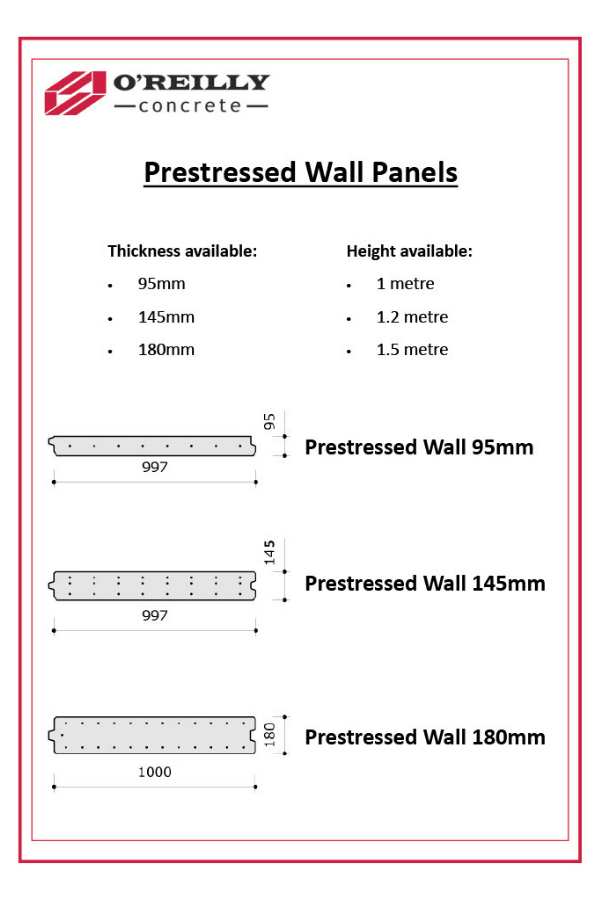

Prestressed Wall Panels

Pre-stressed concrete wall panels are the most cost effective solution for industrial and agriculture buildings.

They allow for usage of maximum strength with minimum wall thickness.

These wall panels are particularly suitable for industrial units, storage units, bulk grain stores, agriculture sheds, general warehousing, earth retaining walls, compost and waste storage. They can be designed to suit your exact needs and can be built horizontally or vertically depending on the job requirements.

The edge detail of each unit is designed to form a tongue and groove joint. These interlinking joints not only lock units together during construction, but also act as a load transfer to spread weight between all units in a wall.

This feature is particularly useful in dissipating impact loads from vehicle collision. The joints are also designed to accept a polyurethane mastic sealant, providing water tight seal