The Role and the ever evolving Benefits of Technology in a Large Precast Company

Technology is continually evolving in all walks of life and has been moving rapidly especially in the last decade. Large precast companies may have initially been slow to adapt but they are making strides and are catching up with the pack at a rate of knots. No one recognises the significance of technology and the need for change as much as O’Reilly Concrete’s Technical Director, Richard Kowalski.

Richard has seen and experienced the journey technology has embarked on and he has spearheaded the journey made by O’Reilly’s in recent years. Richard acknowledges the incredible impact that technology has had on the Precast Industry as a whole in recent times and it’s something that the O’Reilly Group have embraced when so many others have just stood back and waited in the crowd for someone else to make a move.

[fusion_builder_container hundred_percent=”yes” overflow=”visible”][fusion_builder_row][fusion_builder_column type=”1_1″ background_position=”left top” background_color=”” border_size=”” border_color=”” border_style=”solid” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”no” center_content=”no” min_height=”none”]

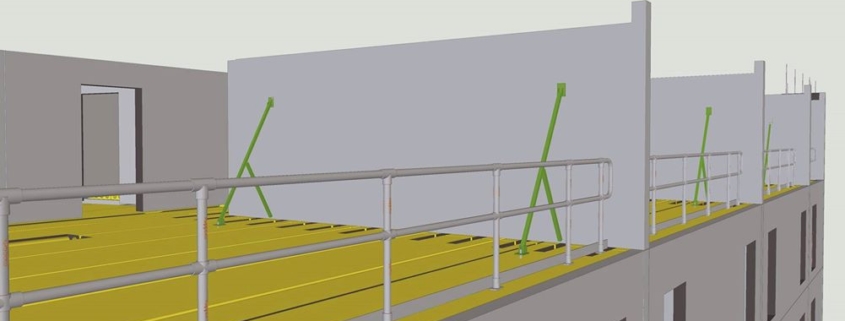

O’Reilly’s made their first big move in the technology sector when BEAM production was introduced before the vast majority of people and companies even heard of the term. O’Reilly’s developed the first BEAM project in Ireland in 2014, a huge milestone for all concerned. 3D modelling is another major facet which enables so many different aspects. For example, design solutions or materials of high performance concrete which gives very high-quality concrete as opposed to ordinary concrete. Sustainability is also a huge factor with O’Reilly’s using GGBS to reduce their carbon foot. According to Richard, the hope is to have the Cardiff factory fully automated in the production precast walls panels in the near future. Needless to say, this would be another giant step in the technological journey with modern technology in the form of Artificial Intelligence or Augmented reality. “The digital data in the factory and on sites is there but it is but it is just a case of devising a model to use features like AI and AR. The vision is fitters using these on an everyday basis and actually visibly viewing everything before they even begin to fit.”

There are a vast array of advantages and benefits to integrating technology into Precast industries. Manufacturing suddenly becomes much more efficient in terms of cost, time is saved as well as improved quality. Richard gave a simple solution which laser projections provide for shuttering, for example, drawings being sent directly to fitters eliminates any potential errors such as human error which can now be avoided with the aid of technology.

The advantage of fitting crews using handheld devices will help to eliminate paper which in turn will reduce time. Bar coding and tracking will make trace-ability easier leading to better control from factory to site. The aim for O’Reilly’s and any other large Precast industry is to continually search for better ways to provide a service for clients, better cooperation between engineers and design teams through the use of BEAM models which save time and reduce unnecessary work on site. The exchange of information for clients and the option to view the proposal in 3D Tender models helps to build better understanding and relationships between the company and client.

Richard is honest and speaks his mind and despite all the benefits, he does not hide from the difficulties and challenges which technology does inevitably bring. He admits he is constantly learning and the fast nature of technology developing can prove difficult to follow. “Everything goes towards simplicity; augmented reality or artificial intelligence, people need to be trained properly to read drawings in the correct manner. Anyone can view a virtual reality sketch however it is crucial you understand it and know how to build it. For example, the iPhone is very simple to use hence why it is so popular, simplicity is the key to be more accurate and successful.” The underlying message here is that you need to have a step by step procedure which deliver a faster and better quality service.

Richard recently spoke at the Tekla UK Concrete Show in the UK and he finished his presentation with the quote “if you don’t adapt you will die.” People often freak out when they hear the term ‘Artificial Intelligence’ or’ Augmented Reality’ but Richard feels it is not rocket science to pick these features up and implement them successfully. “You don’t need a Master’s degree to use AI or AR, iPhone users adapting is the prime example of this. Technology is part of your life and work, if you neglect it or fail to work with it and against it, you will inevitably fall behind.”

Over the last years 13 years since Richard began in O’Reilly’s, the company has made incredible strides from using standard 2D design to using BEAM, 3D modelling and augmented reality in such a short space of time. Whilst the Concrete industry in the technology sphere is growing every day, there is still work to be done. However, buildings and cities are now being built in the virtual reality world before work on site even begins.

It is clear to see from talking to Richard that he has a real passion for technology and he is constantly looking at ways and means of improving the way things are done and how you can learn from previous jobs and make the required adjustments to improve future projects. “There are always better ways of doing things in terms of safety, construction, reducing waste, reducing cost. It is just a case of learning from your previous errors and mistakes and putting things right or else you will find yourself disappearing from the market. The key is to find new ways of completing things and explore alternatives to stay ahead of competition.”

Before becoming the technical director of O’Reilly Concrete in 2014, Richard was a draftsman at first when he arrived in 2005. 6 months later he was appointed as a senior engineer designer so the ever-evolving nature of the world and technology has created a role which did not exist a decade ago which is quite remarkable. This position is vital to co-ordinates all the aspects of Research and Development, integrate technology, develop new products and create future plans in terms of all technical aspects.

The role requires a good deal of research to learn about new phenomenon’s which are emerging every day whilst also keeping a close eye on competitors along with market trends. This enables Richard and O’Reilly’s to stay one step ahead of the competition. The primary goal is to be the market leader and this is achieved through flexibility and adaptability in terms of quality and design. The Hilton Hotel project in Heathrow in the UK was a huge challenge in terms of safety and exposure and modifying to meet the Heathrow authorities’ requirements. For example, activities cannot disturb or interfere with the public and the airport more specifically. You must adapt or else you will die…[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]