Interview with Maurice Rowntree Agricultural & Prestressed Wall Sales Manager

What products are you selling to the Agricultural Industry?

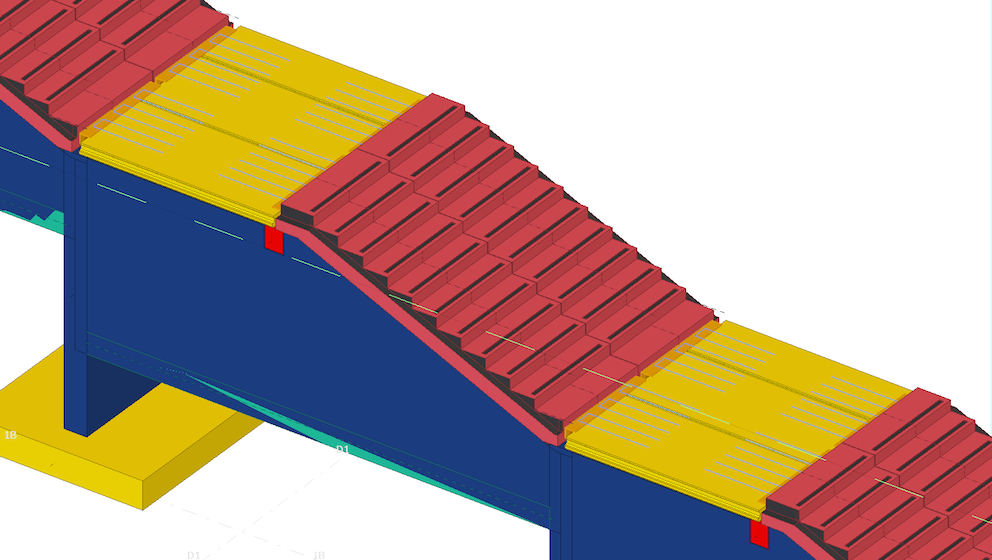

Mainly Prestressed Walls, which are used for different applications within the agricultural industry. We produce 3 different thicknesses of walls for different applications – 95mm, 145mm and 180mm thick walls. For example 95mm is used for cattle sheds, 145mm is used for load bearing walls, storing grain etc and the180mm is used for larger grain stores etc with a greater loading capacity.

Other agricultural products are Precast Slats, Cattle Slats, Cattle Troughs, A Walls, L Walls, Precast Tanks, Slurry Channels

We make innovative bespoke solutions – for example a 20000 L precast concrete tank which is ideal as a reception tank for example in the dairy industry where the flow of manure can be cleaned off easily and efficiently.

Tell us a bit about Prestressed Walls?

Prestressed walls are used for grain stores, cattle sheds, and all types of housing for animals. Farms are generally large in the UK, with very large grain stores.

In the UK generally agricultural buildings are made using prestressed concrete walls and not cast in situ (pour the walls). In Ireland the agricultural industry in the main still works with cast in situ.

Prestressed walls are a great quick fix solution, you can have a shed up in a day…whereas cast in situ could take up to a week.

Another benefit is that you can take the prestressed wall out, clamp them to the steel and if required make modifications for other uses.

Here at O’Reilly Concrete we are hoping to see the use of prestressed walls increase in the Irish market as we get the message out about how efficient prestressed walls are.

The good news is that the message is getting out there – in Ireland when we do sell prestressed walls to a farmer, a neighbour will almost always come to us for the same solution as he’s heard about us from the customer.

Farmers are also particularly interested in the flexibility we can provide with our A Walls and L Walls.

What’s the difference in an A Wall and an L Wall?

An A Wall is used for dividing up a shed and can be used for either side eg if you have barley and maize in the same shed or store. An L Wall can also be used as a divider, but typically will be used as a retaining wall eg when there is a steep clay bank it can be used to prevent landslide.

What is your biggest selling product in the Agricultural Industry?

Prestressed walls. Along with having 3 different thicknesses’ we also have 3 different heights or modules 1m, 1.2m and 1.5m. So you can use a combination of them to get whatever height you want. This provides you with a range of options, for example on a 95mm thick wall you can have a 1M, 1.2 or 1.5 m high wall. You have a possible 9 combinations of wall size.

Do you make walls specifically for each job?

Yes we do. While a lot of storage facilities or sheds built are typically 15 or 20 feet from steel to steel, we will make them to the specific length required, whatever is needed.

This is one of the advantages we can offer the agricultural industry over others – we have our own in house engineering design team, so each panel can be designed to take whatever the loading requirement is. For example we can decide how many strands are used in each wall providing the best engineering solution and value for the customer.

We also provide the farmer with a specific drawing with a layout of all the panels in place, and when we send the walls to him, each panel has a label reference on it, which corresponds with the drawing so he can see exactly where each panel has to go. So for example when a load of panels arrives he knows which to leave out first, in what order to start building the wall. This saves a huge amount of time and makes the process much more efficient.

Do farmers install their own panels, or does ORC do that?

We find in the UK the great majority of jobs are supply and deliver only. In Ireland we mostly supply & fit. We can work directly with the farmers needs.

Do you supply other products to or have repeat business from the farmers?

While we deal directly with the farmer or client, a lot of our work comes via steel fabricators who are actually putting up the sheds. They put up the steel, the wall panels and roof cladding. They are putting up sheds on an on-going basis so in that way we have repeat business as we develop a strong working relationship with them.

Do you have an example of any challenging situations, which O’Reilly Concrete has helped to solve?

We’ve had situations for example where a farmer can’t get a reception tank big enough. We’ve come in with a specific tank size, specific wall panels to suit and created a unique solution for him. We will always review the problem and come up with a solution for the customer.

We have now also a sectional tank, so if the tank for eg 20m x 2.5 m wide, we can give them in 1.5m sections so they can have the exact length you want. We have developed this so we can provide as much flexibility as possible, and unique solutions can be provided.

Are there any changes or trends happening within the agricultural industry?

A lot of big grain companies in the UK are now actually going much higher in building walls so they can create volume instead of building wide stores. We are now looking at providing a thicker wall to suit this trend. This means less land being taken up, more efficient use of space.

What the biggest advantage you provide to customers over your competitors:

Customer service – we look after our customers within the agricultural industry along with the steel fabricators very well as it’s very important they get the best quality and service. We build up a strong relationship so they know we are 100% reliable, providing the highest quality and service. Delivering on time is crucial and we ensure this is done every time.

Which steel fabricators do you work with?

They range from very small to quite large industrial, nationwide steel fabricators who either supply the building or supply and fit themselves.

Examples include:

AC Bacon East Anglia

John Ruck Construction

Supercraft Structures Ltd

What Agricultural Shows do you attend

In the UK, we do the Lamma show, the Cereals event in Peterborough, Royal Highland, Welsh show, and a number of other small community shows. We bring a stand and the products, meet the end user, contractors, and the full range of people involved in building for the agricultural industry.

[fusion_builder_container hundred_percent=”yes” overflow=”visible”][fusion_builder_row][fusion_builder_column type=”1_1″ background_position=”left top” background_color=”” border_size=”” border_color=”” border_style=”solid” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”no” center_content=”no” min_height=”none”][fusion_button link=”http://www.oreillyconcrete.com/contact/” color=”default” size=”” type=”” shape=”” target=”_self” title=”” gradient_colors=”|” gradient_hover_colors=”|” accent_color=”” accent_hover_color=”” bevel_color=”” border_width=”1px” shadow=”” icon=”” icon_divider=”yes” icon_position=”left” modal=”” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ alignment=”left” class=”” id=””]CONTACT US TO FIND OUT MORE[/fusion_button]

[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

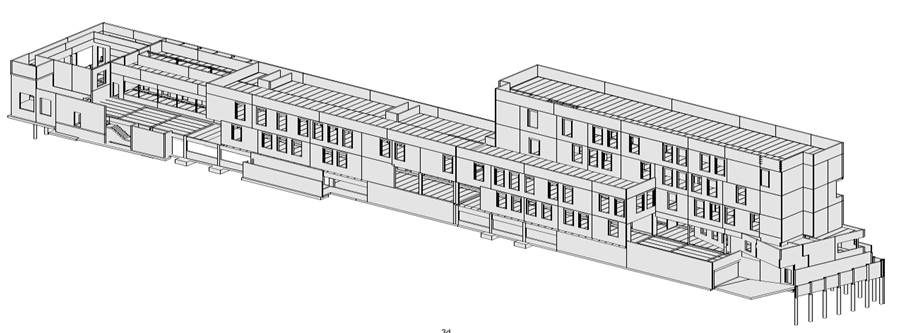

School principal Caroline O’Reilly said staff and students are delighted the building will finally be going ahead.

School principal Caroline O’Reilly said staff and students are delighted the building will finally be going ahead.